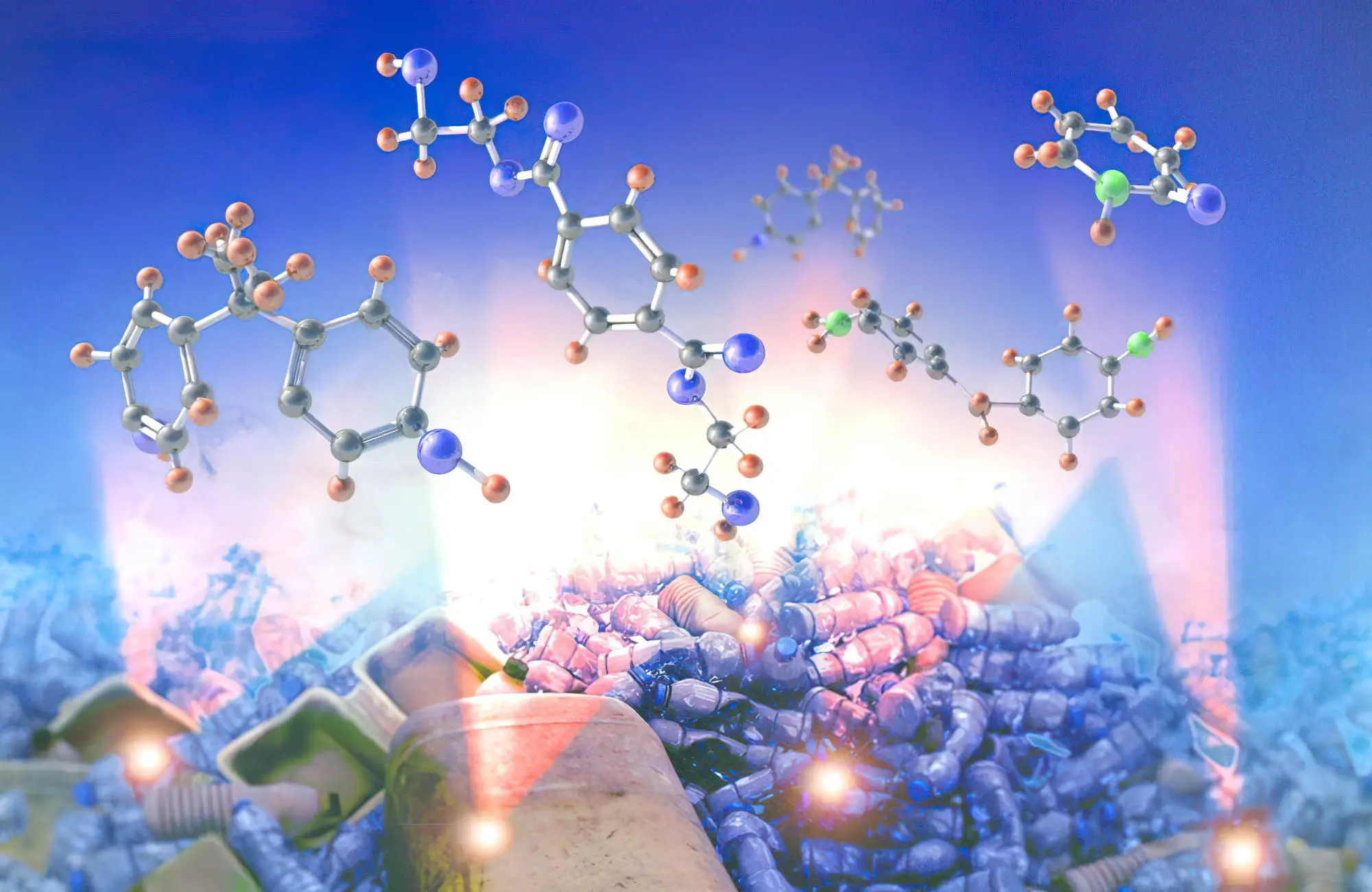

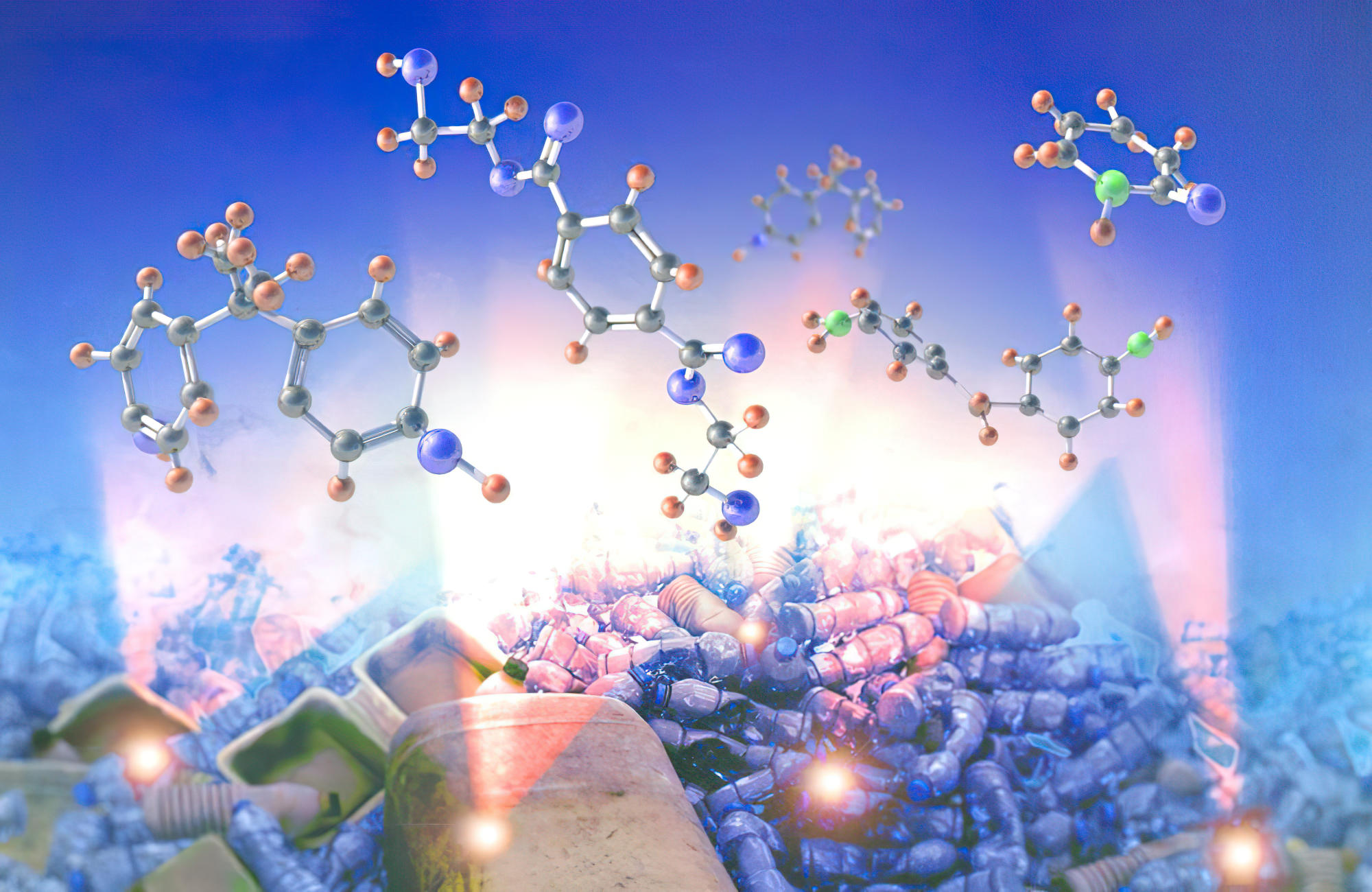

Valuable chemicals are selectively produced from mixed plastic waste by an ORNL-developed plastic deconstruction process. Credit: Tomonori Saito, Md Arifuzzaman and Adam Malin, ORNL/U.S. Dept. of Energy

Mixed plastics can be transformed into useful chemicals.

Nearly 80% of plastic waste ultimately finds its way to landfills or lingers in the environment. Scientists at Oak Ridge National Laboratory have pioneered a method that transforms traditionally unrecyclable mixtures of plastic waste into useful chemicals, offering a new approach in the fight against worldwide plastic pollution.

The technology, invented by ORNL’s Tomonori Saito and former postdoctoral researcher Md Arifuzzaman, uses an exceptionally efficient organocatalyst that allows selective deconstruction of various plastics, including a mixture of diverse consumer plastics. Arifuzzaman, now with Re-Du, is a current Innovation Crossroads fellow.

Production of chemicals from plastic waste requires less energy and releases fewer greenhouse gases than conventional petroleum-based production. Such a pathway provides a critical step toward a net-zero society, the scientists said.

“This concept offers highly efficient and low-carbon chemical recycling of plastics and presents a promising strategy toward establishing closed-loop circularity of plastics,” said Saito, corresponding author of the study published in Materials Horizons.

Reference: “Selective deconstruction of mixed plastics by a tailored organocatalyst” by Md Arifuzzaman, Bobby G. Sumpter, Zoriana Demchuk, Changwoo Do, Mark A. Arnould, Md Anisur Rahman, Peng-Fei Cao, Ilja Popovs, Robert J. Davis, Sheng Dai and Tomonori Saito, 24 July 2023, Materials Horizons.

DOI: 10.1039/D3MH00801K